Bio-circular pipe systems with full traceability

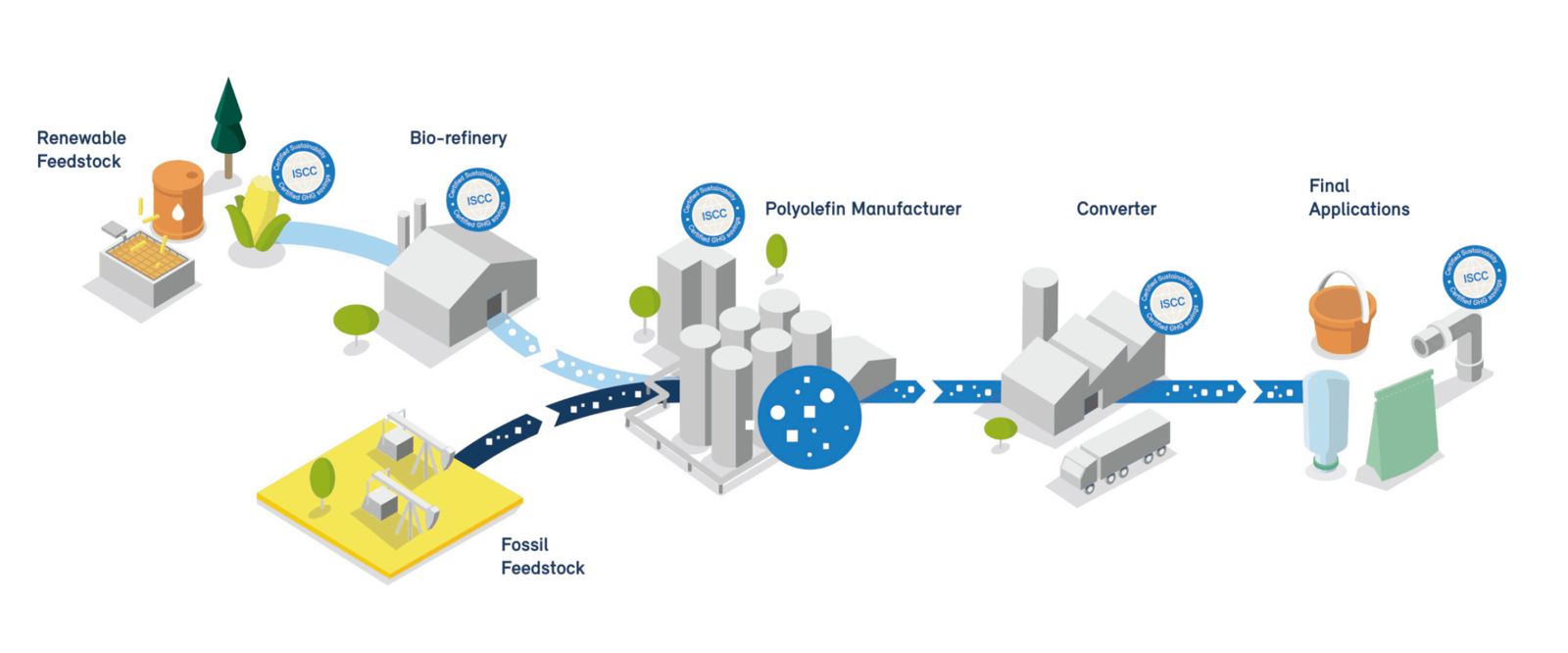

Hallingplast is ISCC PLUS certified and offers pipes where the raw material originates from non-fossil sources according to the mass balance principle. This means that existing infrastructure and production can be utilised.

In concrete terms, the mass balance principle means that raw materials from fossil-free sources are physically mixed with raw materials from fossil sources at the beginning of the value chain. Therefore, we cannot guarantee that the material in the physical pipe is fossil-free. What we can guarantee is that a corresponding amount of fossil-free raw material is put into the value chain and used somewhere in the world. Each stage of the value chain is certified and issues a certificate to the next stage, ensuring full traceability. Each stage must have a system controlled by a third party that ensures that no more fossil-free material is sold than is purchased.

Benefits of purchasing ISCC PLUS certified products:

Lower climate footprint with fossil-free raw materials

Hallingplast can, through the ISCC PLUS certification scheme, offer pipes without fossil content. ISCC PLUS covers several categories of non-fossil raw materials, and Hallingplast supplies pipes made from bio-circular raw materials. These raw materials originate from waste, which after further processing is converted into valuable materials for the production of pipes. The certification requires annual auditing performed by an independent third party, ensuring that our products meet the necessary certification requirements.

The use of bio-circular materials results in a significant reduction in carbon footprint compared to traditional plastic. Bio-based pipes also help promote circular economy by minimizing the use of fossil raw materials in plastic production.

Our raw material suppliers deliver bio-circular raw materials with ISCC PLUS certificate to Hallingplast. This guarantees that the origins of the raw materials are waste products, and that the production of these materials does not occupy areas that could have been used for food production.

100% recyclable PE and PP

We use only virgin polypropylene (PP) and polyethylene (PE) in the production of pressure pipes in order to ensure the highest possible quality. These raw materials have no known harmful effects on health and the environment and can also be reused 100% as raw material in new production.

Thanks to the chemical stability of PE material, pipe systems made of virgin polyethylene have a practical service life of at least 100 years when placed in soil or water.