Hallingplast SESU

– unique pre-weighted underwater pipeline with no need for concrete weights.

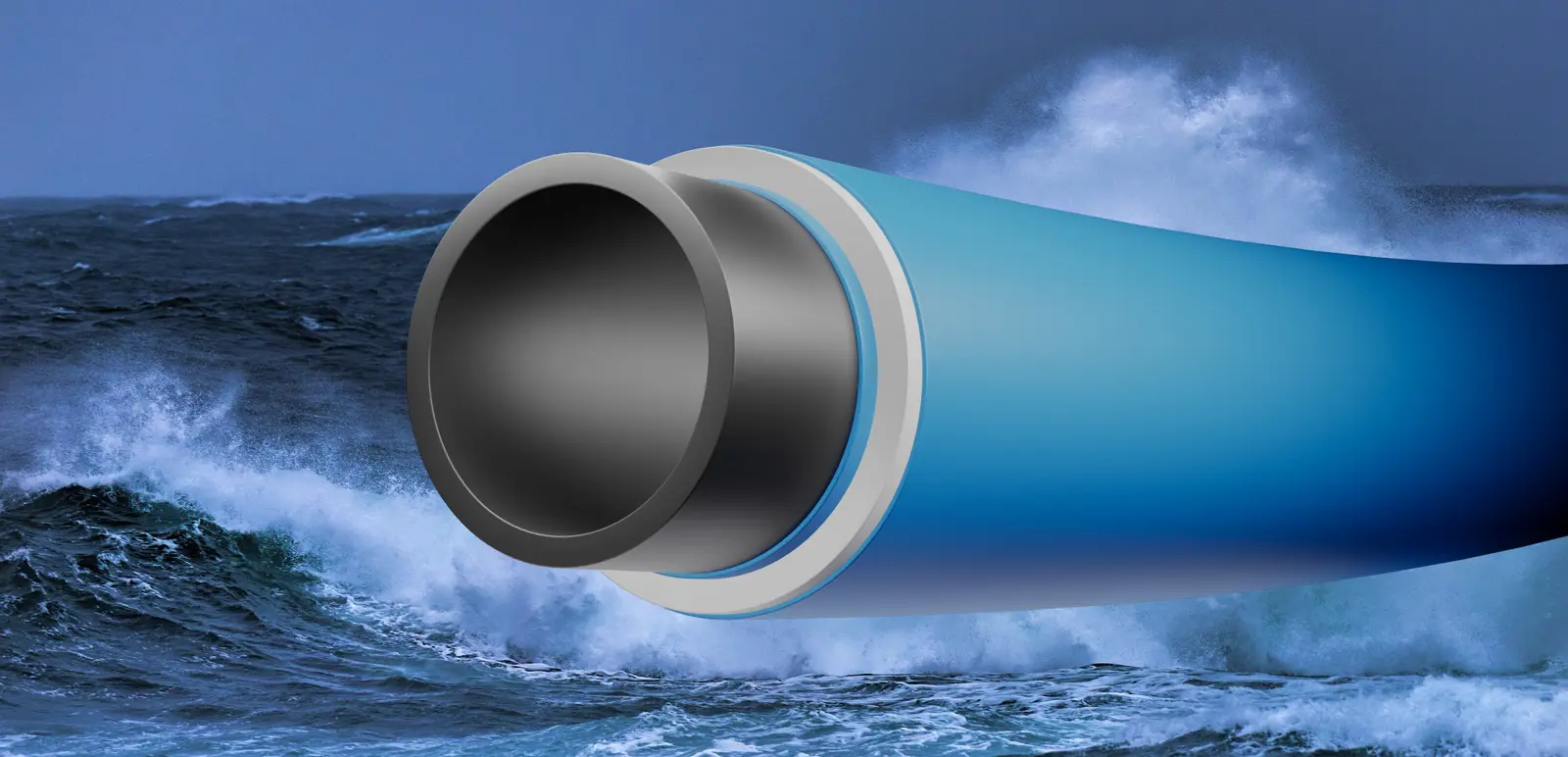

A common method for laying and submerging the underwater pipelines is to use concrete weights attached to the pipe, which is a resource-intensive and time-consuming process. By identifying shortcomings in existing solutions, we have been able to develop Hallingplast SESU (“Self-Submerging PE pipe”) – a unique, pre-weighted pipe that is both easier and more efficient to install and work with, but above all, provides a safer pipe system with a long service life and more secure pipeline ownership.

Instead of concrete weights, the weight in Hallingplast SESU consists of a heavy, homogeneous jacket with the same density as concrete. The result is a design that provides more efficient logistics and handling for the installer, as well as significantly faster installation and a more robust solution for the pipe owner.

Both for water supply and sewage and for cable ducting

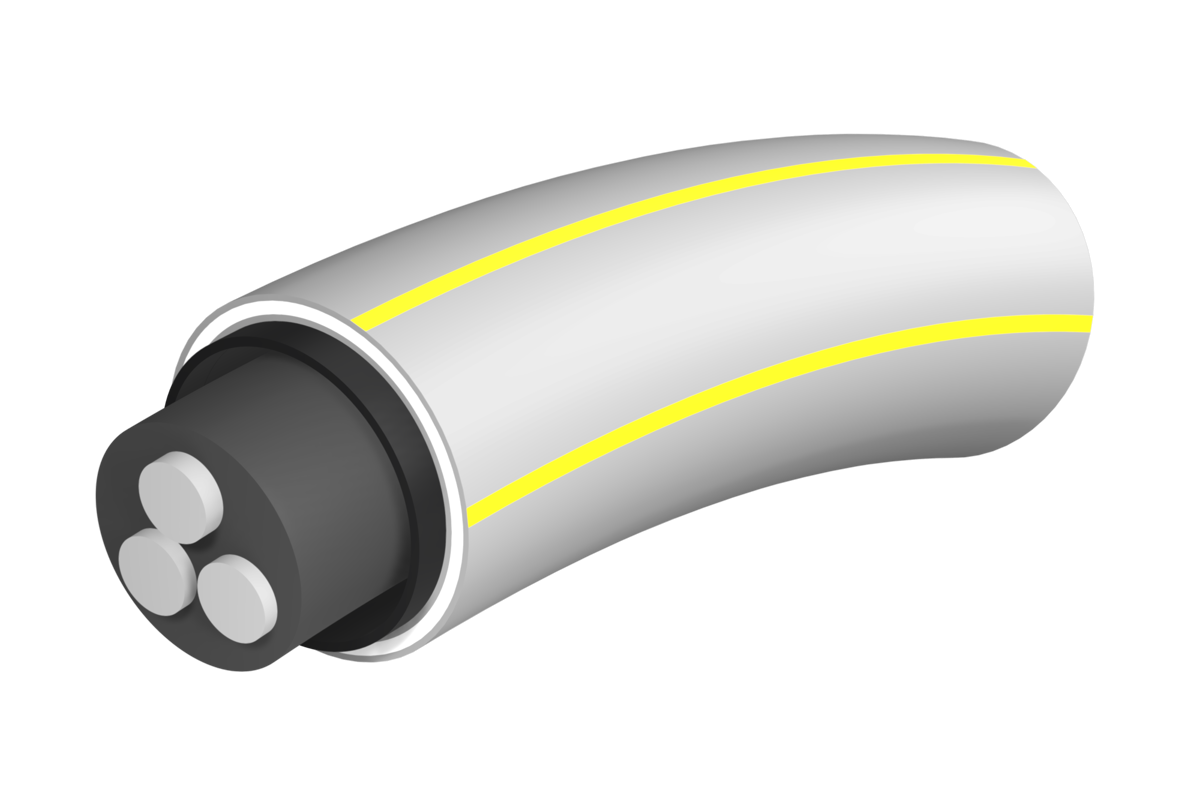

Hallingplast SESU is available for both water supply and sewage and for cable ducting. The major benefit of Hallingplast SESU CABLE is that you can easily replace a power cable, for example, which is not possible if you use a reinforced underwater cable.

High precision and efficient installation

The design of Hallingplast SESU makes it possible for underwater pipelines to be laid with great precision. Only a few small boats are required to fine-tune the routing of the pipeline before it is submerged to the bottom. This is a major advantage in cases where the bottom characteristics or existing underwater pipelines need to be taken into account.

Hallingplast SESU gives you a smooth pipe without accessories such as concrete weights and clamping straps, which means that the entire pipeline has the same service life. Because the pipeline is close to the bottom and has no protruding parts, the risk of fishing gear or anchors getting stuck is also minimised – providing safer and more secure pipeline ownership.

Long service life – in most cases at least 100 years

The weighting is produced under controlled conditions in the factory around and along the entire pipe. This results in a non-corrosive design where all materials will have the same or longer service life than the media pipe itself. In most cases, it provides a life expectancy of at least 100 years. The built-in weighting also provides increased protection against external damage from fishing and anchors and a reduced risk of snagging.

Benefits of Hallingplast SESU:

- Faster installation

- Gentle without heavy lifting

- Requires less workspace

- Protective jacket

- Smooth outside

- Customised weight grade

- Maximum service life for the entire pipeline

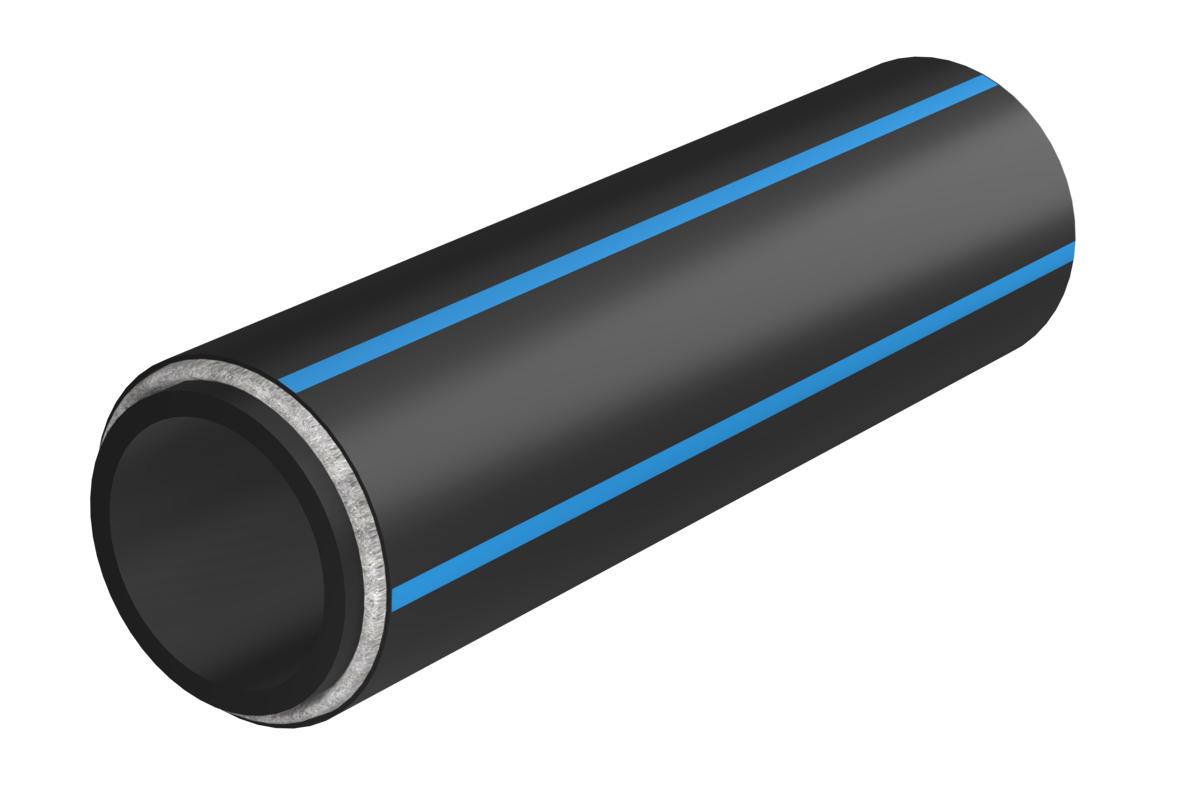

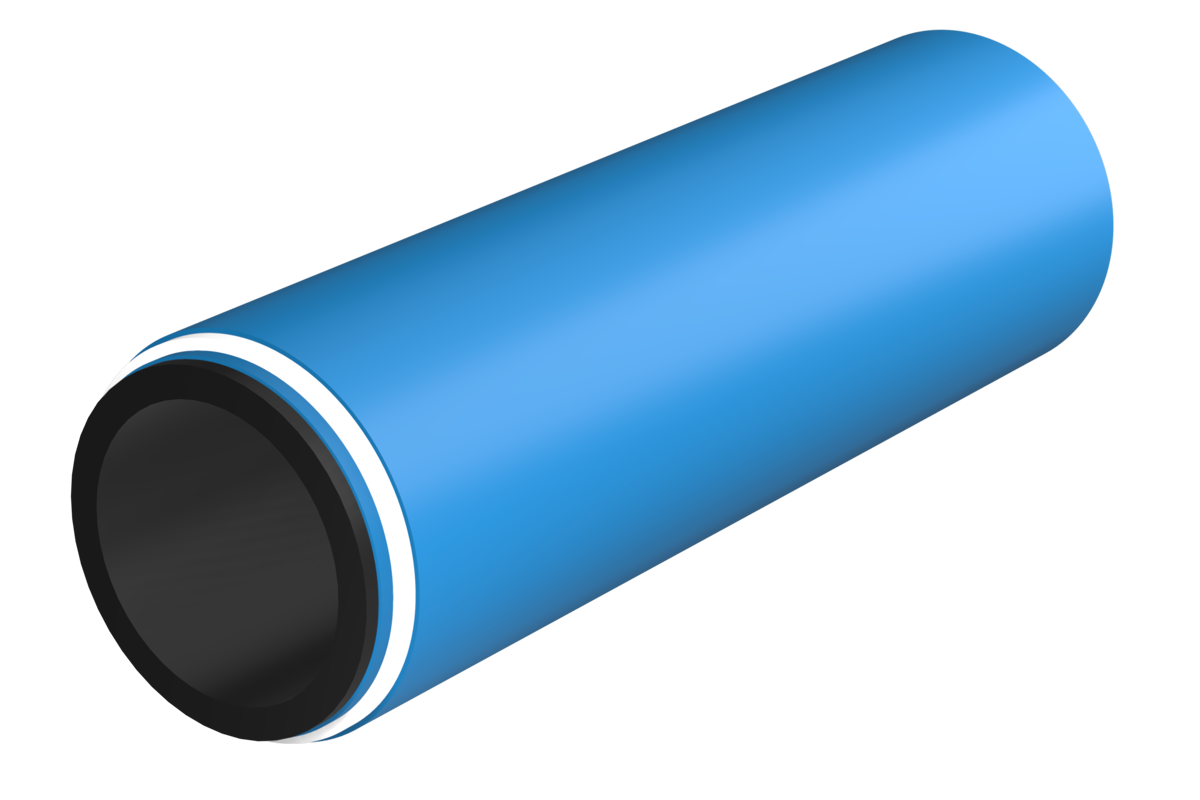

Hallingplast SESU comes in three different versions in dimensions Ø 32 – 1000 mm

- Hallingplast SESU – for water supply and sewage – dimensions Ø 32 – 315 mm

- Hallingplast SESU XL – for water supply and sewage – dimensions Ø 250 – 1000 mm

Intended for water supply and sewage requiring large-scale underwater pipelines. - Hallingplast SESU CABLE – for cable ducting – dimensions Ø 32 – 315 mm

Cable protection pipe for laying cable and fibre optic conductors through seas and lakes. Also suitable for landfall installation.